X-Rings (Quad Rings): What They Are and Why They’re Useful

Share

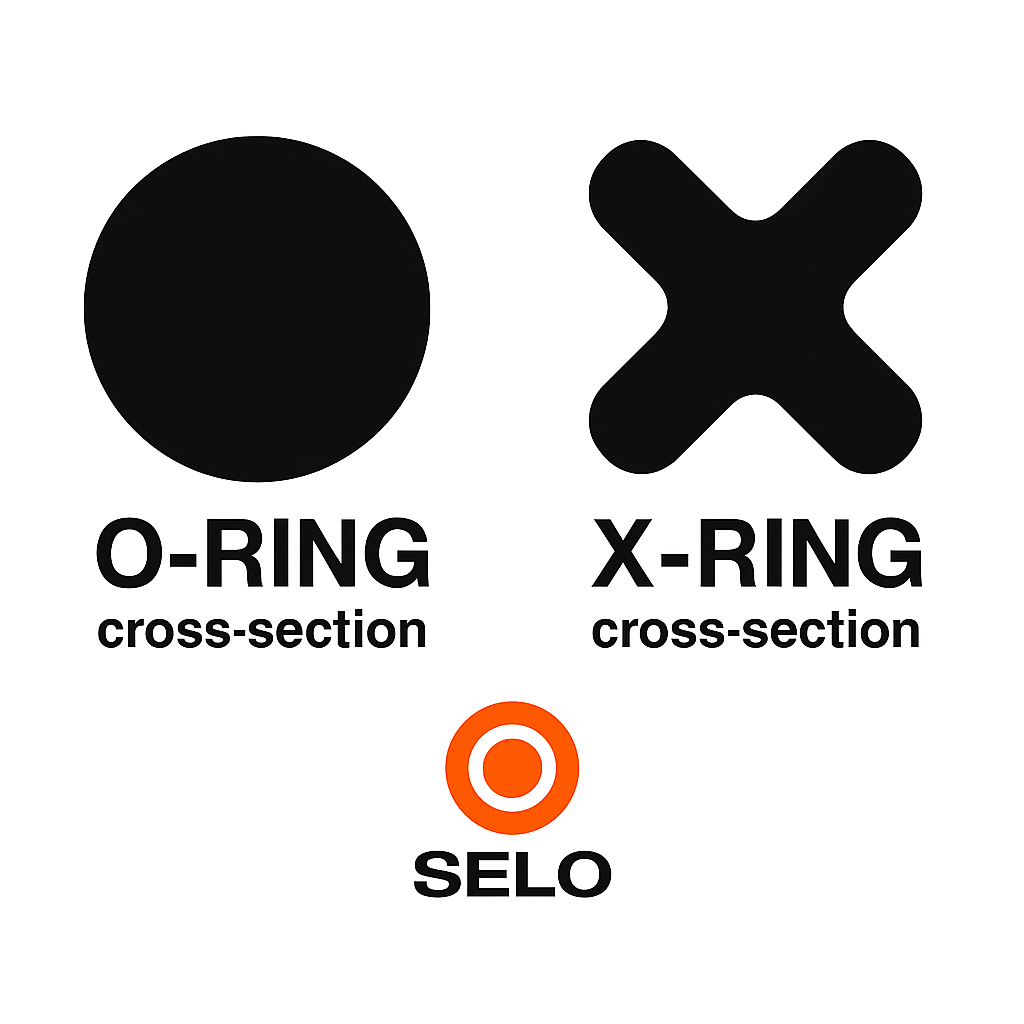

Most people know about O-rings. They’re simple, circular seals that get used everywhere from engines to garden hoses. But have you come across X-rings — also known as quad rings?

At first glance, they look similar to O-rings. The difference is in the profile. Instead of being round, X-rings have an “X” shape when you cut across the cross-section. That one change gives them some unique advantages:

-

Better sealing – The four lips of an X-ring create multiple sealing surfaces. This means less risk of leaks, even under pressure.

-

Less friction – Because the design spreads the load, X-rings can reduce wear and running resistance compared to O-rings.

-

Stay in place – The shape helps them resist rolling or twisting inside the groove, which is a common issue with O-rings in dynamic applications.

They’re often used in hydraulics, pneumatics, and any application where reliability matters.

Right now at Selo, we stock FKM (Viton®) X-rings, known for their excellent chemical and temperature resistance. They’re ideal for demanding environments. Next up, we’ll be adding NBR (nitrile) X-rings, a more cost-effective option that covers a huge range of everyday uses.

So whether you need a high-performance seal or a practical all-rounder, you’ll soon be able to choose the right X-ring for the job right here at Selo.